ECODROP

I see great potential for optimization in the pool sector.

For decades, the same technologies and products have been offered, while there are so many new and innovative products on the market...:

![ECODROP: Swimming pool without chemicals ECODROP: Swimming pool without chemicals]() Why is toxic chlorine still used in swimming pools today?

Why is toxic chlorine still used in swimming pools today?- Are there other methods besides halogens such as chlorine or bromine to keep the pool water clear?

- Why is swimming with a counter-current system so uncomfortable?

- What materials are pool basins made of and what are their advantages and disadvantages?

- Why is it rare to find a professional hydromassage in a swimming pool?

- How to heat a pool efficiently with the sun?

- Is automatic level control in swimming pools really so expensive and does it have to be so noisy?

- Does the pool piping always have to be buried and incur tremendous costs when it needs repairing?

- Quartz sand, zeolite or filter glass, which is better suited for the filter system?

Summarised answered: Until now, pool owners have accepted these facts and paid a lot of money for their standard pool. Why should the providers change this?

I have spent two years searching for the answers to these questions and found solutions.

From these findings I have developed a chrome steel container pool that combines everything.

"Running a pool free of chemicals" or "bathing in drinking water", that was my goal!

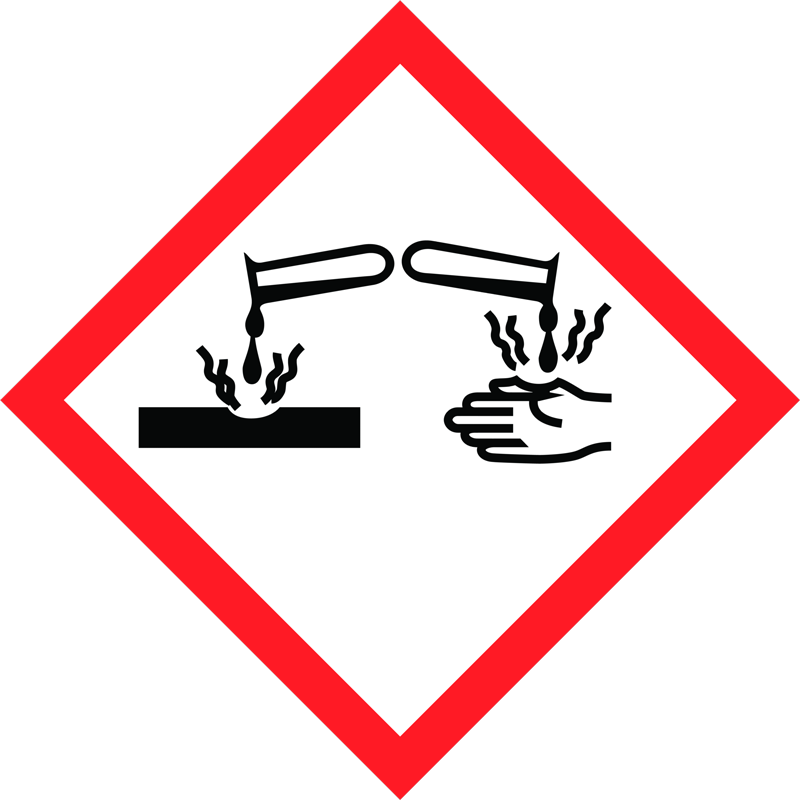

Chlorine is a very reactive element. It has been classified as so toxic that it is in the highest toxicity category. It also bleaches out dyes. (find out more here (German))

Chlorine is a very reactive element. It has been classified as so toxic that it is in the highest toxicity category. It also bleaches out dyes. (find out more here (German))

Drinking water in Switzerland is allowed to have a maximum chlorine content of 0.1 mg/litre.

Pool water needs a concentration of 0.5-1.2 mg/litre chlorine, depending on the temperature, meaning that pool water treated with chlorine must be disposed of via the sewage system, because the water exceeds the limit values by 5-12 times and is highly harmful to the environment.

Chlorine stimulates the build-up of limescale in the pipe systems and the pump, which greatly reduces the life expectancy of the latter.

In other words: chlorine kills organisms, which is why the pool water remains clear.

If the pH of the water rises above 8, the effect of chlorine is severely limited, even at high doses.

This is why the second chemical comes into play: ph-minus (e.g. sodium bisulphate or sulphuric acid).

What does chlorine do to the human organism? Red eyes, dry skin, bleached hair and skin are all symptoms of caustic reactions. Children also often swallow pool water when playing: what does this do to our bodies?

If you are interested, I refer you to the German Green-Peace Studie.

Salt electrolysis produces sodium hydroxide, chlorine and hydrogen from common salt and water. It is safer and easier to use - the result is about the same.

![ECODROP: Clear pool water without chemicals ECODROP: Clear pool water without chemicals]() Yes, there is!

Yes, there is!

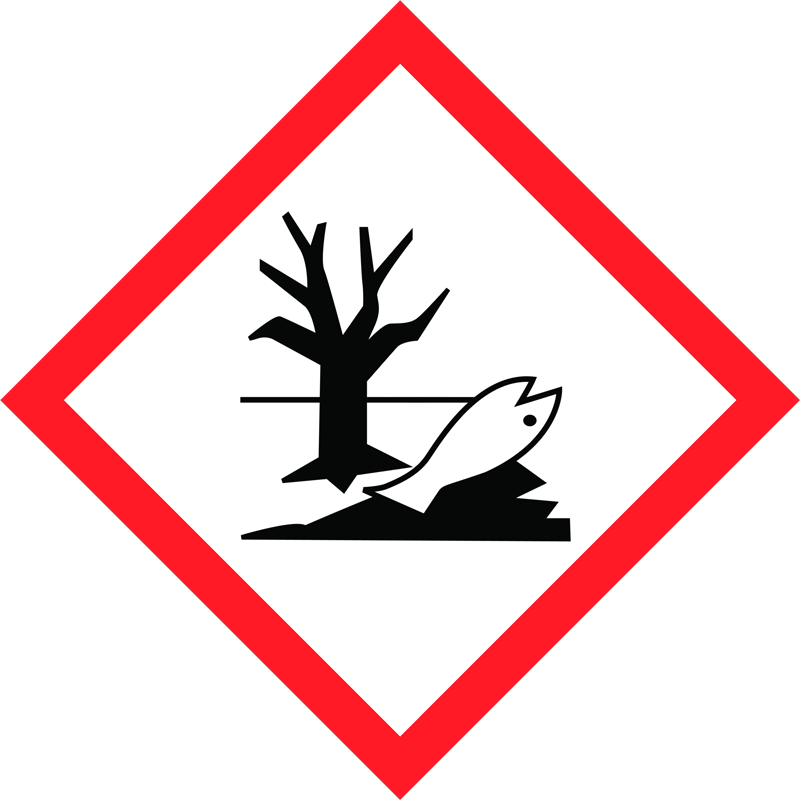

It has been on the market since 1989, is licensed by NASA, NSF and UL and is used in private pools, public pools, Jacuzzis and amusement parks around the world (especially in warm countries). It uses a combination of copper, ozone and CO2 and costs a fraction to maintain compared to a chlorine, bromine or salt electrolysis system.

Bathing in drinking water!

So by combining copper, ozone and carbonic acid, your pool water becomes crystal clear, is easily winterised and your family can bathe and enjoy themselves in pure drinking water. The water is so pure that it can be used in the garden for irrigation without any problems and can seep away without any restrictions.

Clearwater Pool Solutions Switzerlandoffers this solution...![]() Clearwater Pool Systems

Clearwater Pool Systems

Copper is a vital trace element and is responsible for the energy production of the cells with oxygen (cell respiration), as well as for growth. We need around 1.5-3 mg/day.

The legal limit for copper in drinking water in Switzerland is 1.5 mg/litre.

Copper already has a lasting effect on algae at a concentration of 0.15-0.2 mg/litre, whereby the water is still of the best drinking quality!

Ozone is highly toxic and enormously reactive - but highly unstable. It kills bacteria and viruses around 3,000 times faster than chlorine and produces pure oxygen as a by-product. In addition, ozone reacts to organic compounds such as sweat and fats (sun creams, body fats) and causes them to oxidise.

The half-life of ozone is about 37 minutes; in heated and agitated water, the half-life is reduced to less than one minute and forms pure oxygen. Thus, ozone is completely safe for the treatment of drinking water or pool water.

The ph in the pool water is especially important when using chlorine and ideally lies between 7.1-7.6. Strong acids are used for this purpose.

However, the pH is directly related to the carbon dioxide dissolved in the water. We know carbonic acid from mineral water and most sweet drinks. It is used to prolong the shelf life of the drinks. So if you replace the CO2 that escapes from the water into the atmosphere, the ph remains stable.

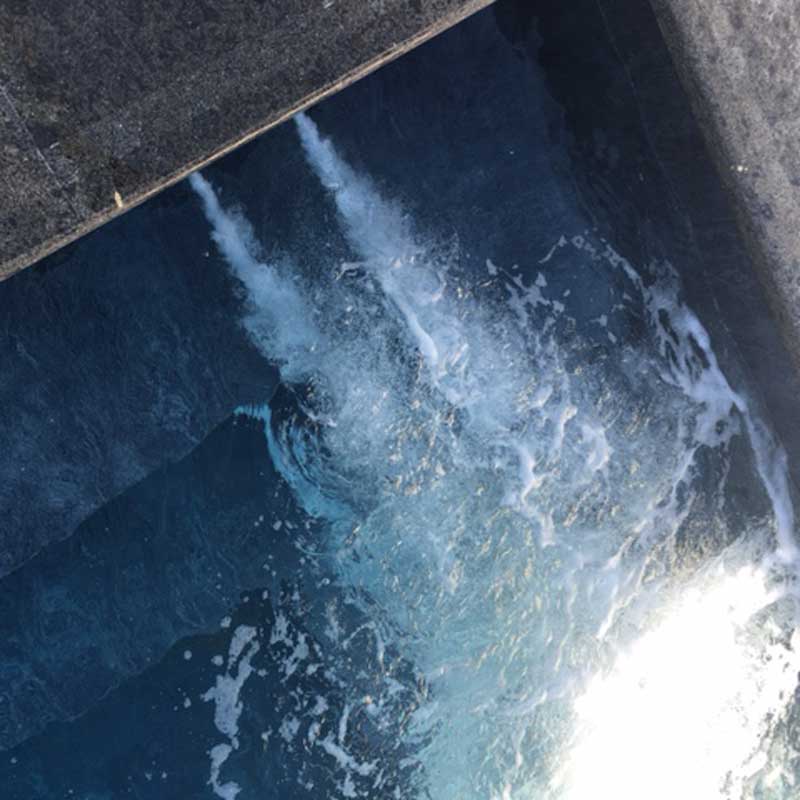

Have you ever trained with a counter-current system?

Have you ever trained with a counter-current system?

If you have, you will probably have had the following experience:

- If you are too far away, the water pressure is too weak.

- If you are too close, the water jet is much too strong.

- If you are at an angle, you will be turned.

- The system is incredibly loud and consumes a lot of electricity.

- Simoutanious swimming of two people is impossible.

Conclusion: Most systems are useless for effective training.

The German product, BaduJet Turbo Pro, was developed for effective swim training of the national swimming team.![]() BaduJet Turbo Pro...

BaduJet Turbo Pro...

Plastics

Kunststoff-Poolwannen sind sehr beliebt. Sie sind günstig, dicht, einfach zu reinigen und können in verschiedenen Formen hergestellt werden. Kunststoffbecken eignen sich aber nur auf stabilem, flachem Untergrund.

Polyvinyl chloride (PVC), glass-fibre reinforced polyester (GRP) and polypropylene (PP) are mainly used. All these types of plastic are made of petroleum.

The combination of chlorine and UV rays dries out the plastic, making it brittle and pale. It is possible to prevent this aging effects with complex chemical treatments.

Polypropylene (PP) is one of the plastics that is classified as harmless to health because it does not contain plasticisers. However, PP decomposes with UV radiation and loses elasticity below 0°C. These tubs have the shortest lifespan.

Polyvinyl chloride (PVC) contains plasticisers that are considered a health concern. PVC causes serious health and environmental problems, from production to disposal.

Glass-fibre reinforced polyester (GRP) is the most sustainable, durable and safe plastic tub. However, during production and processing the companies must respect high protective regulations. The visual ageing of the material is also not ideal.

Concrete

Concrete is not waterproof, but can be made water-resistant with chemical additives. Nevertheless, micro-cracks develop over time into which water penetrates. A concrete pool quickly becomes in need of renovation. Concrete is therefore very expensive to maintain.

Concrete is not waterproof, but can be made water-resistant with chemical additives. Nevertheless, micro-cracks develop over time into which water penetrates. A concrete pool quickly becomes in need of renovation. Concrete is therefore very expensive to maintain.

If the concrete is lined with a plastic membrane, the pool is cheaper to maintain. These plastic foils have a rough surface and can fade. This increases the energy and cleaning costs.

Concrete can be coated with epoxy resin, which makes it waterproof. However, if there are cracks in the concrete (e.g. subsidence of the soil, shifting of the soil or water from outside), the resin also suffers. In this case, you can sandblaste the surface and repaint it at any time.

Steel with epoxy resin coating

Steel pools are robust, do not have to be sunk into the ground and can be set on any soil. It is preferably to install them in a container (container pool). Steel rusts. This can be prevented with a complete epoxy resin coating (inside and outside) or alternatively with a plastic foil on the inside. Again, if epoxy resin coated, the surface can be sandblasted and repainted at any time. As these tubs are very smooth, the cleaning effort is small. It is important that the seams are cleanly welded (preferably double welded).

Steel retains its raw material value and the basin can be lifted out and moved at any time.

Stainless steel

INOX steel pools are among the most noble of all pool types. Stainless steel also rusts, especially when in constant contact with corrosive agents such as chlorine. This type of pool is very robust, completely UV-resistant and suitable for any surface. Here, the quality of the weld seam is also the most important criterion.

Stainless steel is very expensive, but retains much of its raw material value. Basins can be placed on the ground or sunk into the earth. On slopes, the free side can be combined with glass windows.

Not all hydromassages are equal

Hydromassage is a collective term for therapies that stimulate the circulation of the skin, muscles and soft tissues with the help of water pressure, heat and sometimes water/air mixtures. Tensions are relieved gently.

Hydromassage is a collective term for therapies that stimulate the circulation of the skin, muscles and soft tissues with the help of water pressure, heat and sometimes water/air mixtures. Tensions are relieved gently.

This type of therapy is problematic for people who are sensitive to skin irritations, as the chemicals contained in the water are massaged into the skin along with the water pressure.

Whirlpool

The combination of light water pressure, air bubbles, heat and weightlessness is suitable for relaxation and recuperation. However, this is not possible in swimming pools as the heat is not sufficient.

Combination devices: counter-current system / massage

Many counter-current units can be used directly for massage or have hoses that can be used to massage specific parts of the body. The disadvantage is that the pressure is often too high. Attaching the hoses is tedious and the massage effect is not very relaxing. Without a hose, only the upper back can be massaged.

Massage jets

You may know this type of hydromassage from public SPAs. Nozzles of different strengths are located in the wall at different heights, where different parts of the body can be massaged comfortably. This is rarely found in private pools. It requires a separate pump with high-quality jets and a technical room near the pool. This purchase is expensive and cannot be combined with plastic pools.

The steel/chrome steel container pools from oekopool.ch have a separate massage corner with professional chrome steel jets.

One thing is clear: if the sun is not shining or if it is cold, the pool will not be heated.

But when the sun is shining, you can use solar energy efficiently and cost-effectively with absorbers to heat the pool and maintain the desired temperature. There are three methods.

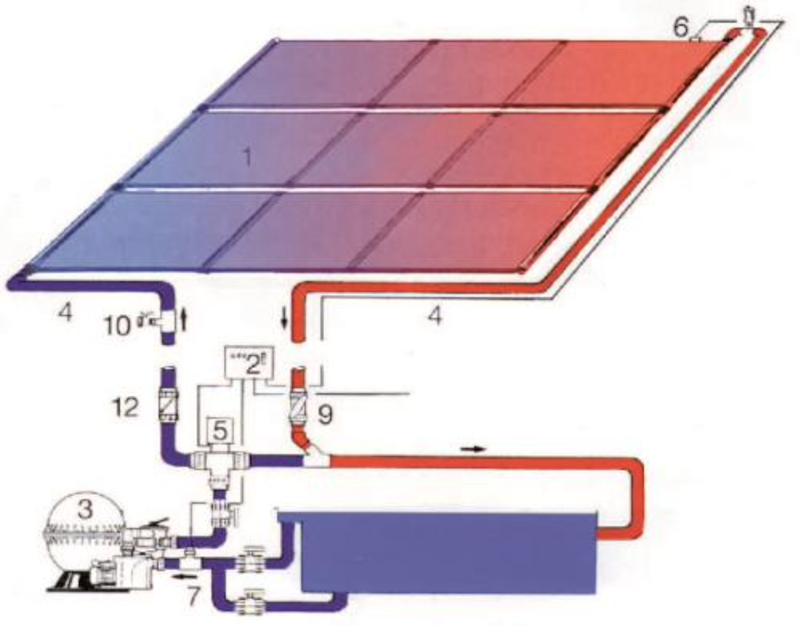

- Running over the filter pump via a three-way ball valve using a differential temperature control.

![ECODROP: Solar heating: operation with filter pump ECODROP: Solar heating: operation with filter pump]() This connection type is ideal if the absorbers are not installed higher than 6 m above the water surface. The three-way ball valve is installed in the pressure line of the filter system. The differential temperature control switches the three-way ball valve over when the absorber temperature is higher than the swimming pool water temperature. The filter flow is then pumped through the absorbers. The heated water flows back into the filter circuit via a T-piece.

This connection type is ideal if the absorbers are not installed higher than 6 m above the water surface. The three-way ball valve is installed in the pressure line of the filter system. The differential temperature control switches the three-way ball valve over when the absorber temperature is higher than the swimming pool water temperature. The filter flow is then pumped through the absorbers. The heated water flows back into the filter circuit via a T-piece. - Operation with own pump and differential temperature control integrated in the filter circuit

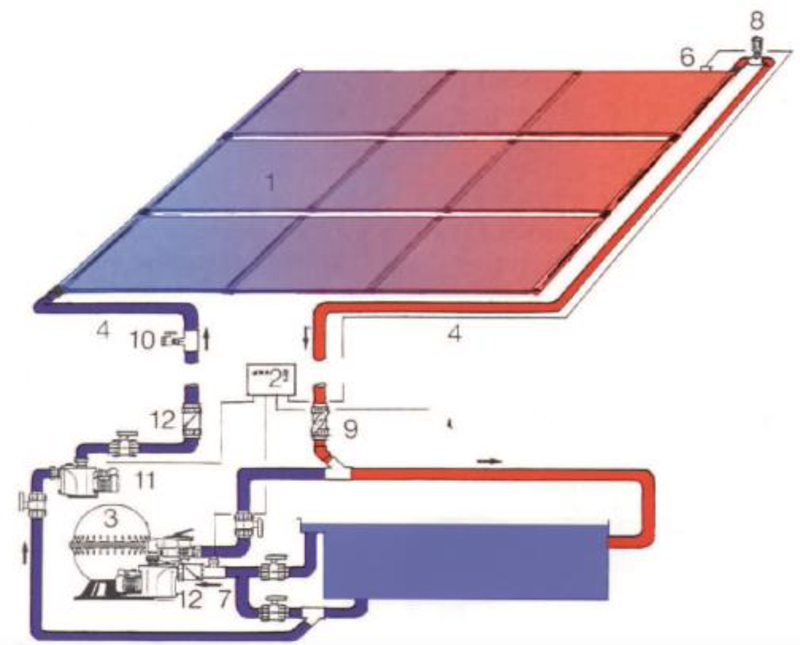

![ECODROP: Solar heating: operation with separate pump integrated in the filter circuit ECODROP: Solar heating: operation with separate pump integrated in the filter circuit]() The installation of a separate pump for the solar heating makes sense or is necessary in some cases if the delivery height from the water level to the absorber field is more than 6 m or is far away. The water is branched off by a T-piece in front of the filter and pumped through the absorbers by the additional pump. This pump is switched by the differential temperature control, ensuring that the pump only runs when there is actual heat gain. The filter and solar pump are controlled independently of each other - the filter circuit is not burdened.

The installation of a separate pump for the solar heating makes sense or is necessary in some cases if the delivery height from the water level to the absorber field is more than 6 m or is far away. The water is branched off by a T-piece in front of the filter and pumped through the absorbers by the additional pump. This pump is switched by the differential temperature control, ensuring that the pump only runs when there is actual heat gain. The filter and solar pump are controlled independently of each other - the filter circuit is not burdened. - Operation with own pump and differential temperature control: Piping independent of the filter circuit

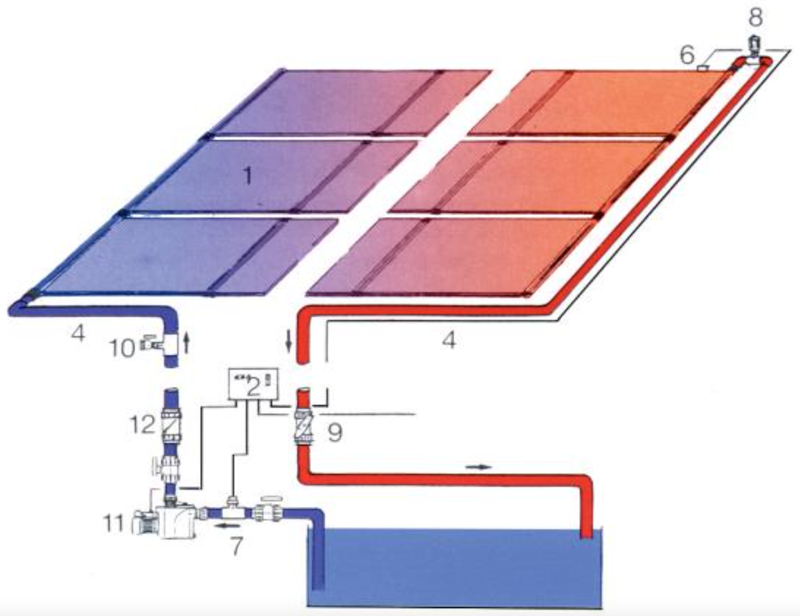

![ECODROP: Solar heating: operation with separate pump in own circuit ECODROP: Solar heating: operation with separate pump in own circuit]() Here, too, the pump is only started up when the outside temperature is higher than the pool temperature and only until the desired pool temperature is reached. This installation makes sense if the hot water circuit can be operated completely separately from the filter system. This solution protects the filter system.

Here, too, the pump is only started up when the outside temperature is higher than the pool temperature and only until the desired pool temperature is reached. This installation makes sense if the hot water circuit can be operated completely separately from the filter system. This solution protects the filter system. - It is also possible to run the separate circuit via a heat exchanger. The advantage is that a thermal fluid can be used, that is more heat efficient and frost-proof. The disadvantage is that it requires an additional equalisation basin and an expensive heat exchanger.

There are basically two types of automatic level control:

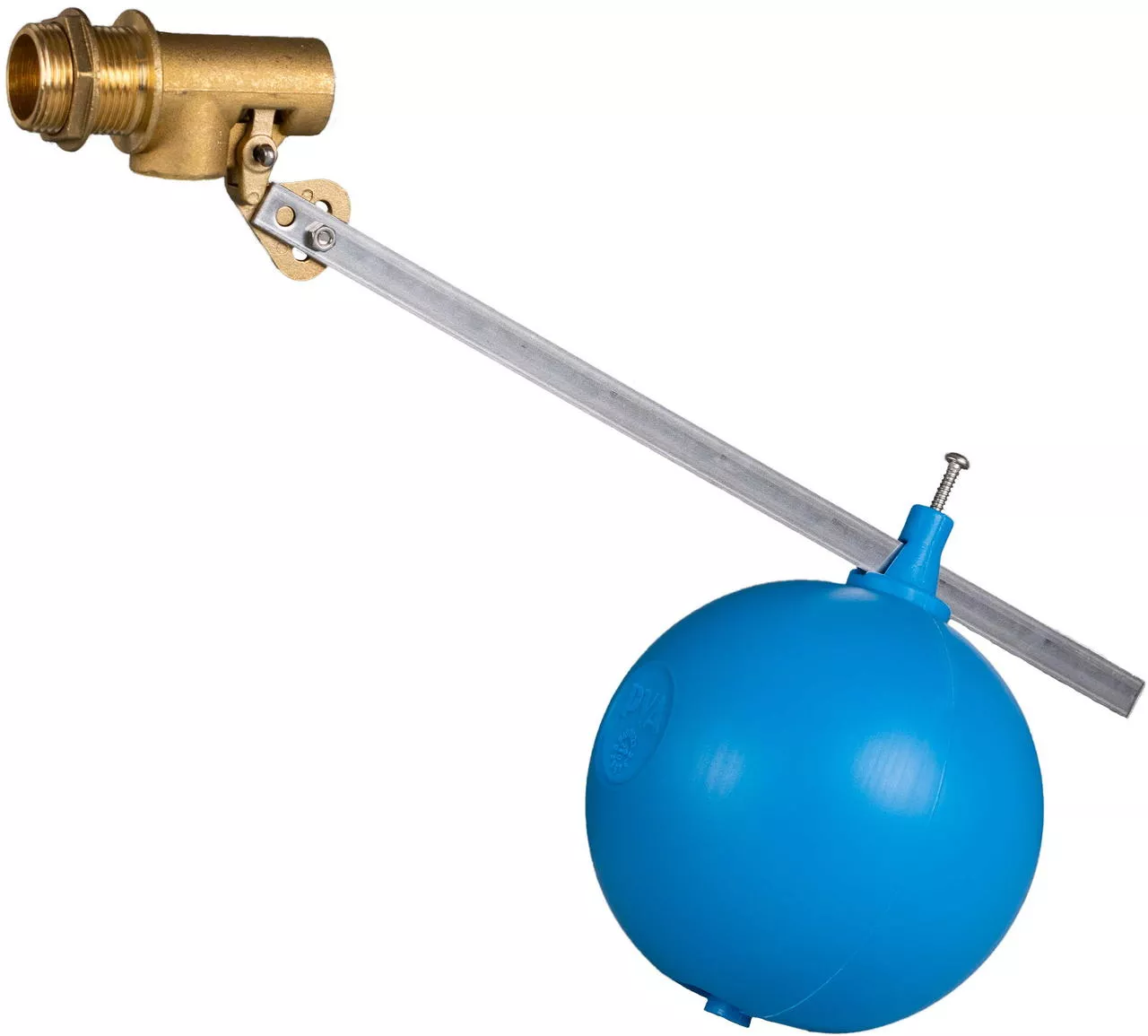

- Level regulation with a floating valve

![ECODROP: Level regulation with a floating valve ECODROP: Level regulation with a floating valve]() This type works with any liquid, whether it conducts or not. Good quality floating valves snap shut when the level is reached - cheap variants close slowly and generate noise in the process. The disadvantage of float valves is that they require a relatively large amount of space and are always on the surface. Also, the level is always filled up immediately, which increases water consumption.

This type works with any liquid, whether it conducts or not. Good quality floating valves snap shut when the level is reached - cheap variants close slowly and generate noise in the process. The disadvantage of float valves is that they require a relatively large amount of space and are always on the surface. Also, the level is always filled up immediately, which increases water consumption. - Level regulation with a solenoid valve

![ECODROP: Level regulation with a solenoid valve ECODROP: Level regulation with a solenoid valve]() This solution requires a switching device with one or two sensors and a strong solenoid valve. Only conductive liquids work with these sensors. Please note that rainwater conducts poorly or not at all.

This solution requires a switching device with one or two sensors and a strong solenoid valve. Only conductive liquids work with these sensors. Please note that rainwater conducts poorly or not at all.

1st sensor: as soon as the water level falls slightly below the threshold, the solenoid valve opens and fills up with water. This is not always useful, especially when it might rain or bathing quest cause waves that will trigger the valve to open and close constantly.

2nd sensor: Allows a predefined delta in the level without immediately topping up with water. This is the more sustainable and water-saving variant.

All these variants are inexpensive, but the installation in the skimmer is the more costly part. Certainly, there are also skimmers or infinity pools that have an automatic level control built-in. These are usually very expensive.

It is much cheaper to install the valves/sensors in a separate container that is directly connected to the pool and open at the top.

There is no way around pipes when building a pool. The further the distance from the technical room to the swimmingpool, the longer and more vulnerable the pipes are. The most ideal is a technical room that lies directly next to or underneath the swimming pool.

If pipes have to be burried, we would recommended that they are as easily accessible as possible. If the pipes are in a protective cover-pipe, they are better sheltered and possible leaks are immediately detected and can be quickly repaired.

I just don't understand why no pool builder takes this into account.

Natural quartz sand

Natural quartz sand is available in various qualities and grain sizes.

Although quartz sand gets washed, it may contain pollutants. Please make sure that it complies with DIN 12904 (drinking water treatment) when you buy it.

The finer the grain size, the greater the surface area and thus the filtering properties, but the grain size depends on the filter system. Small grains may be flushed out, depending on the filter system. The best results are achieved with three layers of different grain sizes:

- Very coarse quartz sand with a grain size of 3-4 mm is recommended for the bottom layer.

- Somewhat finer quartz sand with a grain size of 2-3 mm is suitable for the middle layer.

- Very fine sand with a grain size between 0.4 mm and 2 mm achieves the best filtering result when it is in the top layer.

It is recommended to fill the filter system only approximately 50% with sand so that the backwashing and swirling of the sand work best. In addition, natural quartz sand should preferably be replaced every 2-3 years, as it tends to clump together and form channels, which considerably reduces the filter performance.

Frequent backwashing helps to keep the filter system running and to change the sand less frequently.

Advantages and disadvantages of quartz sand

The surface of quartz sand is rough and asymmetrical, what increases the filtering effect because suspended particles are retained more efficiently. The disadvantage, however, is that bacteria can also settle in the sand and form a biofilm that protects them from chemicals such as chlorine. In this biofilm, bacterias produce ammonium, which reacts with chlorine to form inorganic chloramines (mono-, di- and trichloramine). Trichloramine causes an unpleasant chlorine smell.

Zeolite

Zeolite is made from stones of volcanic origin and is a mineral powder used as a filter medium for sand filters. Zeolite can be used alone or mixed with sand or filter glass. It is recommended to fill the filter system only 50% to 60% with zeolite and to replace the filter medium every 7-8 years. Order organic Zeolite for your Pool.

Advantages and disadvantages of zeolite

Zeolite offers an excellent filter fineness of 5 microns, which makes it a better performer than any other filter media.

Zeolite has the great advantage that it additionally stabilises the pH value and thus helps to reduce the consumption of pH-correcting agents. It also has the property of absorbing AOX (adsorbable organic halogens). Zeolite is much more expensive than sand but offers better performance.

Filter glass

Filter glass is also available in different grain sizes. The recommendations for quartz sand also apply to filter glass. The quality of the glass is determined by its surface structure and finishing. Dryden Aqua also offers a product called AFM (Activated Filter Material), which has a larger surface area and is negatively charged on top of it.

The molecular weight of the glass is smaller than that of quartz sand. Therefore less weight is needed for the same volume: approx. 20 kg of filter glass has the same volume as 25 kg of silica sand.

Advantages and disadvantages of filter glass

Due to the smooth surface, filter glass has a less effective filtering effect than quartz sand (I don't believe Dryden Aqua). Nevertheless, I agree that it is more difficult for bacteria to settle and there is less clogging and channel formation. It also needs to be replaced less often and thus saves costs.

Due to the lower weight of the filter glass grain compared to quartz sand, the former is stirred up and cleaned better during backwashing, but can be rinsed out sooner.

Conclusion

Quartz sand and filter glass have excellent filtering properties and both are very suitable for filtering pool water. Both products have advantages, but also disadvantages. So you have to decide for yourself which properties are more important to you.

I have decided to mix zeolite with filter glass in three/four layers.

Yes, there is!

Yes, there is!

This type works with any liquid, whether it conducts or not. Good quality floating valves snap shut when the level is reached - cheap variants close slowly and generate noise in the process. The disadvantage of float valves is that they require a relatively large amount of space and are always on the surface. Also, the level is always filled up immediately, which increases water consumption.

This type works with any liquid, whether it conducts or not. Good quality floating valves snap shut when the level is reached - cheap variants close slowly and generate noise in the process. The disadvantage of float valves is that they require a relatively large amount of space and are always on the surface. Also, the level is always filled up immediately, which increases water consumption. This solution requires a switching device with one or two sensors and a strong solenoid valve. Only conductive liquids work with these sensors. Please note that rainwater conducts poorly or not at all.

This solution requires a switching device with one or two sensors and a strong solenoid valve. Only conductive liquids work with these sensors. Please note that rainwater conducts poorly or not at all.